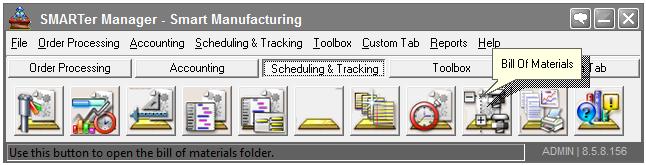

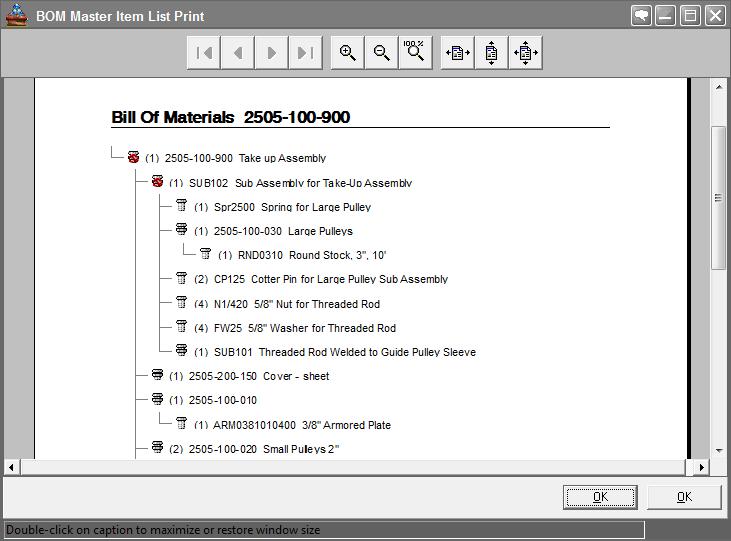

SMARTer Manager’s™ unlimited level, Bill of Materials software (BOM software) module can be used for much more than setting up and maintaining the materials contained in a company’s products. In addition to Engineering’s role to set up and maintain the ingredients contained in an enterprise’s products, common uses of Bill Of Materials to include Accounting’s dependence on it for cost roll-ups for product costing, product pricing and the calculation of work-in-process material variances.

Let SMARTer Manager’s™ Bill Of Materials software empower your company to help ensure product conformance to design specifications and quality control.

BOM Software Benefits

- Reduce the number of plant-floor errors; such as low-level parts required but not purchased

- Automatic notification for purchasing and or production

- ECN (Engineering Change History)

- Complete PLM (Product Life Management)

- Handle items with no routing, or wrong part type codes, components in the Bill Of Materials without item master records, and making parts with no product structure linkage.

- Visual notification of inventory levels

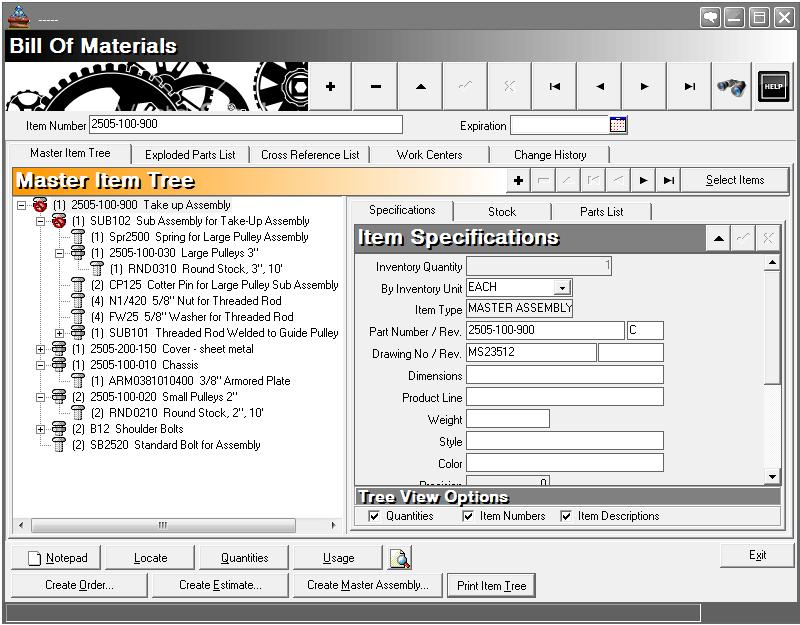

- User configureable Printable master item tree

- Unlimited Bill Of Materials levels, ideal for complex BOM’s

With SMARTer Manager™, audit components on a pick list in real time to ensure that parts and associated quantities are accurate.

Let the power behind SMARTer Manager’s™ Bill Of Materials software also help you find accurate product pricing and calculate any of your work-in-process material variances.

SMARTer Manager’s™ Bill Of Materials management is one of several ways we support the engineering department. How can it help me with product development?

With SMARTer Manager™ you can create and maintain unlimited Bill Of Materials. Our Bill Of Materials implementation includes Change History tracking, Where Used support, and the ability to create both Estimates and Orders directly from Bill Of Materials. SMARTer Manager’s™ CAD image support, red-lining, and comprehensive note management are also excellent tools for keeping production and engineering in sync.