Many industries require that their products and items be tracked for better quality control and with the specific requirement of tracking part identification information. SMARTer Manager™ includes this functionality which provides automatic tracking of serial numbers and lot control for inventory traceability.

With SMARTer Manager you get one software system designed for manufacturing that meets these needs:

- Lot Tracking System

- Inventory Serial Number Tracking Software

- Lot and Serial Number Software

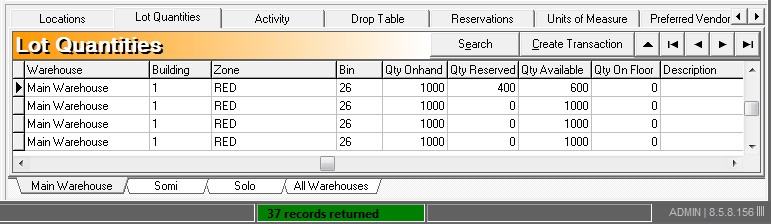

- Multi Lot, Locations and Warehouses

Lot tracking and serial number tracking provides thorough paperless documentation of the specific components used for each part or assembly produced, items carried in inventory, or materials received.

SMARTer Manager™ provides traceability by creating a lot record for each lot number, serial number or grouping of parts, and automatically tracks each part as it flows through the shop floor. For history purposes, the lot number and serial numbers can be traced back to the material the part was produced from. And more importantly, to all customers that received the part.

Lot numbers appear on appropriate inventory reports, such as on-hand by location. A printed or displayed report allows you to search by customer, part number, production order number and/or lot number to find each occurrence of a specific lot number or serial number.

SMARTer Manager inventory management module allows for multiple warhouses and multiple locations. Because of the modules flexibility, ease of use and powerful control you can accomplish SOMI (Supplier Owned Managed Inventory) tasks quickly and easily. Helping to drive cost savings and lower inventory levels for a leaner supply chain. It leads to a pull-based system that helps prevent excess inventory from being pushed into the supply chain. Sometimes referred to as JITI (Just in Time Inventory).

Features

- Sophisticated User-defined serial number pattern.

- Record serial number for components used within a BOM.

- Expiration dates can be defined for any lot.

- Auto serialization upon shipping or receiving.

- On screen inquiry by part, all lot numbers and serial numbers received/shipped for that part.

Benefits

- Lean supply chain.

- Lower inventory levels.

- Prevent excess inventory levels.

- Manage multiple warehouses on a single screen.

- Ability to define traceability requirements on a part-by-part basis, with each part having it’s own special tracking requirements.

- Detailed lot tracking meets Defense and Government requirements

- Auto assign serial numbers, no more manual entry.

- Lot numbers and serial numbers can be assigned at shipping, receiving and material issued before proceeding

- Track customer shipments back to the raw material lot that was used to produce the finished part.

- View on-hand inventory balances with a listing of lot numbers/serial numbers.